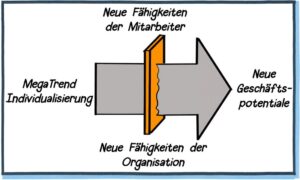

Individualization is one of the trends that is nowadays referred to as a megatrend due to its decades-long development. So is this megatrend of individualization a risk, a challenge or an opportunity for manufacturing companies? For most companies, all of the above apply. The megatrend requires new skills from employees and the organization. It opens up new business potential. At the same time, however, it also poses a threat to companies that do not adapt to the trend in good time. In the first part of the article we focused on highlighting various components of the trend, in particular the aspect of mass customization. In the second part, we will now look at the skills that individualization demands of companies.

Business capabilities: How individualization and company capabilities are connected

A capability is not limited to the knowledge and skills of individuals: Business capability defines the ability of a company to successfully carry out its core activities (Secondary sourcepage 10). Of course, these are based on the skills of the employees and their individual experience. However, they are also based on the capabilities of the organization, i.e. its resources, methods, processes and IT tools.

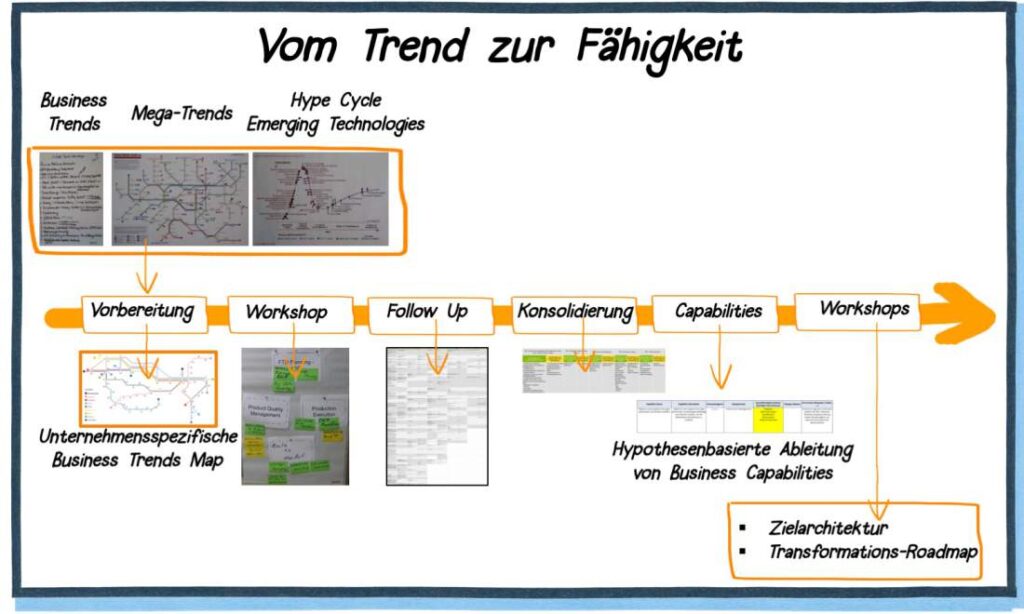

The following illustration uses a project example at a global corporation to show how the capabilities were derived from the most important trends.

If a company wants to be in a position to offer products with variants or even individualized products, then these capabilities are required in a wide range of business areas. Only then can the new business potential be tapped.

The ability to develop a product with variants

In order to be able to develop products with variants efficiently, a high proportion of common parts should be aimed for. To achieve this, products must be grouped into series or platforms in such a way that a common parts strategy can be optimally implemented. Examples can be found among automobile manufacturers, such as for example at BMW.

In order to increase the proportion of common parts across product lines, a cross-series and cross-product line modular system management should be used. In agricultural technology, for example, extensive kits such as a gearbox or electronic control unit can be used in different series, brands or product groups (tractor, combine harvester). One example of this is the agricultural machinery group Agco, where transmissions and engines are used within the group in different brands such as Fendt and Massey Ferguson can be used. The Variotronic electronic operating concept is used in both tractors and combine harvesters. As another representative of the automotive industry, Volkswagen has further developed its platform concept and also relies on the concept of building blocks.

The management of common parts at individual part level has been one of the main tasks of product data management systems since they were first used. Nevertheless, company-wide common parts management - especially in larger companies with different divisions - often still fails due to system limitations. Centralized master data management makes it possible to put a stop to the diversity of parts. If this master data is also combined with forecast data, this enables logistics and purchasing to plan better and realize better conditions in procurement.

The ability to develop a customized product

If you look at their development processes, there are major differences between products with variants and truly individual products. In the one case, the development department can carry out the development completely. In the other case, certain development and validation services can only take place once the customer has expressed the requirement. The ability to develop truly individualized products also requires additional sub-processes and a different organization.

While platform development must pursue product standardization and can initiate this in advance, customer-specific development has the task of reacting quickly and flexibly to customer requirements. This not only results in different processes, but also certain conflicts of interest. A little friction between these different interests can be enormously beneficial in the search for the optimal solution. However, the task of finding this ideal solution should not fall to one department, as this could hinder the process. We therefore recommend an organizational separation between platform development on the one hand and customer-specific development on the other.

In the B2B environment in particular, it is necessary for customers to be able to submit their product requests in as standardized a form as possible and to receive the necessary support. This must take place in coordination with the sales department. One example of this is the Finnish tractor manufacturer Valtra, which has developed the Valtra Unlimited Studio offers its customers the option of being able to incorporate any wishes.

Comprehensive change management within the company is of central importance in this context: Changes to the capabilities of the standard must be known to customer-specific development so that they can be taken into account accordingly. Otherwise, innovative customer-specific development should also be integrated into the standard via the change process.

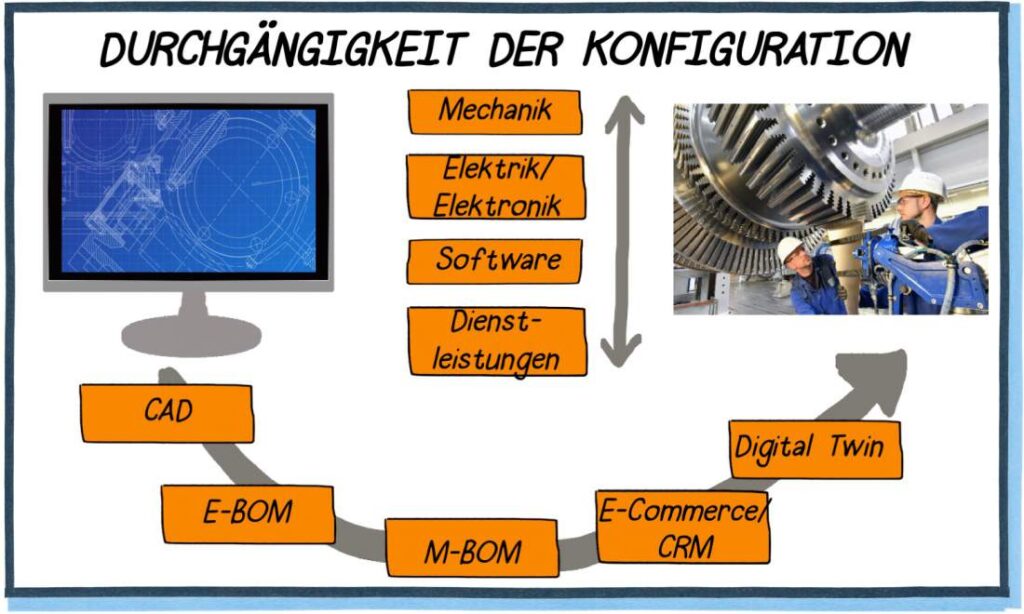

The ability of IT to manage data

The consistency of product and configuration data across the entire process and the entire life cycle must be ensured: from the product idea to the start of production or assembly right through to the end of use. Development and sales must be involved here, as well as purchasing and spare parts management. In addition, the various disciplines of mechanics, electrics, electronics and software must be interconnected.

The company must be able to manage big data from production and product use and link this with product data and customer data. In the context of individualization, product data and customer data are ultimately the basic framework that makes many evaluations with big data information possible in the first place.

The ability to develop complex systems

In the past, most companies developed products that were mainly mechanical. It was not until later that increasingly larger proportions of electrics, electronics and software were added. However, product developments were still driven by the development department alone. Today, however, the impetus for developing complex systems consisting of services, IoT features, software and mechanics is usually provided by business model innovations. In the direction of individualization, this is a completely new approach that must nevertheless be anchored in the company.

The development of complex systems naturally requires numerous new individual skills, for example in the areas of software development, IoT and cyber security. In addition, the development of complex systems requires the ability to integrate and coordinate different areas. Experts with the individual skills mentioned must cooperate with colleagues who have been developing classic products for 15 or 20 years. In addition, design thinking and agile methods be applied in product development.

The ability of development and controlling to determine costs

Many companies offer their standard variants too expensively and their special solutions too cheaply. This is one of the reasons why a company must be able to determine the product costs, process costs and complexity costs caused by variance and individual components. This calculation provides companies with the basis on which they can offer the product to the customer at appropriate conditions. In this way, they also find out whether and which product variants can be eliminated, as many variants are not at all effective for the customer. Only a look at the actual costs helps to create real transparency in decision-making.

The company then needs IT solutions that make it possible to determine the costs as quickly as possible in the event of a quotation. A relatively large amount of time is initially available to determine the costs of a standard product. However, if you want to offer customized products, you need to be able to quickly provide the customer with a house number for the cost of their customization request. Some special machine manufacturers face an even greater challenge, for example if the customer is already using the product and wants a retrofit. This in turn raises a question that not all companies can answer immediately: What is the technical status of the machine used by the customer? This question illustrates how fundamental efficient data networking really is - and what it means in detail in terms of the demands that individualization places on the company's capabilities.

The ability to safeguard in development and prototype construction

With increasing variance and an increase in technical possibilities, the trend is towards securing the product virtually. The solution is to first produce a digital twin instead of real prototypes. This is because a physical prototype is extremely expensive. With virtual validation, costs and development time can be saved accordingly - and many more variants can be validated at the same time. In the automotive industry in particular this concept for several years used successfully.

The interaction between virtual validation and variant configuration is particularly important here, so that all product variants can be validated. This is not just about product validation per se: the manufacturing and assembly process can also be increasingly validated virtually.

The ability of the service department to provide service for a customized product

During production and every service intervention, the installed base, i.e. the documentation of the current status of the product, must be adapted. This is particularly impressive when even car manufacturers today often do not know exactly which vehicles are affected when they launch a recall campaign. Special machine manufacturers still analyze drawings, ask their customers or send a technician with a digital camera to the customer to find out.

If you want to offer professional service with a wide range of variants or individualized products and earn money with them, you need information about the installed parts. The service team needs access to the installed base so that they know what to expect before they travel to the customer. This also makes it clear in advance which spare parts they may need to take with them. In future, digital twins will help to virtually recreate fault situations in order to minimize downtimes and reduce service costs.

How to tap into your business capabilities and new business potential

The megatrend of individualization is one of our key topics in the Projects & Processes for Engineering focus team. We support companies in developing and expanding the necessary skills that have become essential due to the various effects of individualization. We offer customers a two- to three-day in-house workshop to get them started: Together with the customer, we work out the specific effects on their company and derive initial capabilities at a rough level.

(Cover picture: © Patrick Müller)